Now, you have this great urge to own a nice and functioning DIY sex machine.

But you haven’t got the slightest clue where to get the parts. How to identify the best designs. Or where to begin when tying up the components.

If the bill above fits you, then you’re in for a treat. Stick around and get to know how to make a fuck machine at home.

So let’s jump right into it:

Upsides Of A DIY Sex Machines

First off, it saves you money.

The initial investment in making your own sex machine is fairly low.

You don’t need to pay a hefty price to the manufacturer for buying a high-quality product. Some items can easily be purchased at a nearby hardware store and put together yourself.

Secondly, you get to use any material you prefer.

For example, you can get a bigger motor if you want more power. Plus, you can customize and alter its size as per your taste.

Most importantly, these DIY machines can help you achieve better orgasms. It’s like having your own personal sex toy that never gets tired of being used over and over again.

Safety Precautions When Building and Using A Sex Machine

Most of these machines use motorized and electrical components that could be dangerous when mishandled. So it is imperative to know which parts are safe to be incorporated into your machine and which ones should be avoided.

So here are some tips to keep in mind:

- Safety first – Before using your DIY sex machine, thoroughly inspect and test its functionality and cleanliness. Always clean it before and after use to prevent any infection or irritation caused by dust particles or bacteria.

- Use appropriate tools – Use the right tool for the job. For example, if you’re a beginner, you can start with the low-powered and smaller options available.

- Keep everything together – Make sure that all the parts are securely attached to each other so that they don’t come loose and fall apart. Also, ensure nothing is missing before engaging in any play.

How Much Will it Cost?

The answer depends on the deepness of your pocket and how much you are willing to spend.

This is because there are myriads of parts’ options you could use in the assembly. And each one comes with a different price, depending on your location.

That said, you could DIY yourself one for as low as $150, or go to upwards of over $1,200.

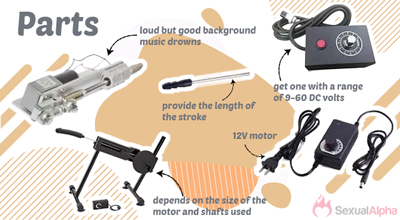

Which Parts Will You Need?

Before we set the ball rolling, here’s a basic list of parts that you need to have. You can find or improvise some of them from your household electronics or garage.

They include:

- Motor – We went with a wiper motor (12V) because it’s accessible. It’s whirring is a bit loud but good background music drowns it like magic. ($45 – $150)

- Speed Controller – You should get one with a range of 9-60 DC volts that can sustain a motor within the same range ($25)

- Power Supply – For our 12V motor, in this case, a 5 to 6A PSU serves the purpose. ($10)

- Casing – Our base’s measurements here is 24” x 9.5”. Measurement for the vertical boards holding the motor and shafts may vary. It depends on the size of the motor and shafts used. ($10)

- A rod with Vac-U-lock attachment – The rods provide the length of the stroke. You will adjust these according to the length that best suits you. Vac-U-lock attachments are available in most retails and you will need to attach one at the end of one rod’s length. ($10)

- Ways to tie it all together – You need screws, bolts, nuts, air tube connectors, thread ball joints, winding ball joints, rigid shaft couplers, and miscellaneous rod parts to cover for any adjustments in your perfect DIY fuck machine. ($25)

How To Build Your Own Fucking Machine?

There are a few ingenious ways around this.

You have to keep in mind that while it’s more affordable to make it yourself, it’s not going to be as pretty as the ones in the stores.

Let’s jump right in:

Option #1: A Prototype Of A Fuck Machine

Process:

- Use a 25mm long joint nut of 8mm that fits with an 8mm rotating arm screw. The stroke length is also the length of the arm and should give room for easy adjustments.

- Attach a ball-joint of a similar threaded 8mm rod at the end of the arm’s length.

- Connect the arm to the stroking shaft using a shaft joint, 8mm holes, and matching screws.

N/B: It’s important to mount the shaft’s bearing to prevent the joints from crashing.

- You need to extend the shafts as they are about 11.8”-12” by default. A simple solution here is a drill length extension that you can fit on the shaft by filing down one end.

- The most suitable way to join these components is through a set of air tube connectors. This is because their female ends are an easy fit on the shaft with the help of tapes.

- The air tube connector’s male part mounts on the suction flat plate or a vac-u-lock adapter.

Simply put, these simple steps will help you close the deal on how to make a homemade fuck machine. Check this tutorial for more detail.

Option #2: The Simplified Sex Machine Design

- Get the $50 drill from your local hardware store and a piece of timber for the base. The measurements for the timber base piece are 24″ length and 9 1/2″ width.

- Next, you’ll need another piece of timer for the flywheel that you will connect with the drill, and it’ll move the rod with a dildo. The size of the circle will determine the stroke length, so choose the size you’d like.

- Then it’s time to connect the drill and speed controller with the base and the flywheel. After, add your rod with Vac-U-lock attachment.

- Using the linear guides, connect your rod to the base, and here you have your structure.

This is a very basic way to build a DIY sex machine that will do the job.

The speed controller will allow you to choose how hard or soft you want the strokes to be, so you have full control of the experience.

Option #3: A Seat Sex Machine

- You’ll need a dildo, a wooden chair, a drilling saw, and fasteners such as nails, screws, nuts, and bolts.

- Create a foundation for the drilling saw using concrete to hold it in place. The handle should be inside the cement with the blade facing up.

- Cut the sharp edge of the drilling saw and leave enough area where you’ll attach the dildo.

- Attach the base of the dildo to the remaining part of the drill saw.

N/B: You may add screws if the material of the dildo allows you to do so. This will help you secure and prevent it from falling off during use.

- Mark a spot on the chair where you’d like the dildo to be inserted. Drill a hole that’s large enough to accommodate the dildo.

- Position the chair over the drill saw and insert the dildo into the hole.

- Switch on the machine to check if the dildo can penetrate through the hole smoothly. If it works well, then it’s time for you or your lady to ride it.

This sex machine is very simple and easy to construct. However, it requires the right materials and tools to function effectively.

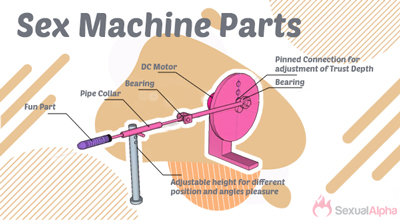

Option #4: A Flywheel Fuck Machine

- For this project, you’ll need a 12V motor, a flywheel, a pushrod, screws, bearings, and support bars.

- You’ll also need a Vac-U-Lock and, of course, a dildo.

- Drill a hole in the middle of the flywheel. You can also drill more holes from the center to the edge of the flywheel with a gap of about 1 inch between each hole if you intend to adjust its thrusting length.

- Then, mount the motor to the side of the flywheel. Once done, you can now attach the screws to secure the flywheel and motor.

- Attach a bearing on the opposite side of the flywheel, and connect a pushrod to the bearing.

- Connect the Vac-U-Lock to the other end of the pushrod and mount your dildo.

- Install the support bars around the machine to ensure it doesn’t wobble while in use.

- And finally, turn on the motor to check if it works fine. If yes, then your fuck machine is ready to go.

Compared to other options, this one might seem quite difficult to build. But it is actually not that complicated to put together. All you have to do is follow the instructions carefully, and you’ll be good to go!

Sites That Help You With Plans, Tutorials And Sell Parts

Still, stuck? Check out sites that offer help on assembling, designing, and parts’ listings.

MachineYourself offers one of the cheapest ways to build a DIY sex machine right off the bat. The Heavy Duty piece only cost $150 and has parts that comprise of:

- Speed control device @ $25.

- Harbor Freight drill @ $45.

- Delrin bought from eBay @ $25

- Wooden 16” by 3” sheet, ½” thick @ $10

- Bolts, screws, miscellaneous rod parts, etc. @ $25

- Aluminum tube that’s 3’ of ¾” @ $10

Process:

- You mount the drill using the holes in its casing. Bearing in mind the measurements of the flywheel determines the mount’s height.

- Make a flywheel from a thick oak board ¾” thick by cutting an 8” circle that provides an equal length in the stroke. This length varies by drilling extra holes in an arc from the center in 1” intervals.

- Counter-drill the back of the flywheel to host male ends of the ball joint linkage. The rods aren’t long enough to cover the ¾” board.

- Use a threaded hex standoff with a ¼” bolt for the flywheel’s center post.

- To use linear guides, cut them from the Delrin block and fit a ¾” shaft by drilling a ⅞” hole on it. Take note of the plastic heats and shrinks during and after drilling. Maintaining extra ⅛” allows easy linear action.

Watch the full DIY video tutorial here.

As of now, MachineYourself is now discountinued. However, you may now look at the needed materials at some local hardware stores or online retailers.

This site is a one-stop-shop for DIY sex machine gears. The top ones include:

- Detachable hand control ($30)

- Complete power lines ($120)

- Locking joint systems ($40)

- A vast listing of motors

It has a neat documentation of how to build the LoveMachine42People. It gives a detailed step-by-step walkthrough that includes the coding spec of the sex machine.

Hismith gives the best deals on three crucial parts:

- Speed controller (Wired/Remote)

- A powerful motor (24V/100W)

- Power supply compatible with the motor.

Other People’s DIY Fuck Machine Building Experiences

And now let’s check what other people are saying about the topic:

“I’ve thought about this for a long time and its DOABLE but honestly you’ll prolly end up paying more in parts and fabrication for something safe and strong enough as you would for a Hi-Smith off Amazon. You can start with a windshield wiper motor and depending on your existing skills and random materials you might be able to get somewhere without spending tons of money, but the motor alone is going to set you back somewhere between $40 and $100 and then you’ve got to figure out a flywheel and a linear drive linkage and a solid base on which to mount everything. . . ”

And here’s another input if you’d like to go a different way:

“I’ve considered using servos, there are cheap servos (£30) that can handle 60-70 kg/cm, and that should be plenty enough for this application. Basically, you wouldn’t go a full rotation, just back and forth, and you can control the position easily in code, and maybe make some “better than real” movement patterns (say, a high frequency, low amplitude wave overlayed on the main wave).

Anyone tried using servos?”

“It’s real simple to make, you need to spin 2-4 poles in an elipse around a mother with movement distance changing with the distance from the mother, find a way to lock pole 3 into 1 dimension of movement and build a case to hold it still, that’s the basic design principal of them

Materials: motor or engine, durable disc or if not possible a mountable pole, 3 metal poles. 2-3 disc hinge if you don’t have one make them by putting 2 discs on a pole and removing as much friction as possible. Screws don’t Know how much you will need. a screw driver or drill.”

Conclusion

There you have it! Before we drop the mic – it’s our hope that the information here was useful in your pursuit of how to build a fucking machine at home.

The best thing to do is to check out different communities online that share a lot of great information on building your own DIY fuck machine.

You can get help and advice on the whole building process.

So, what are you waiting for? GO FOR IT!!